New generation bimetallic tubes

About us

Etubes B.V. is a manufacturer of cladded and lined bimetallic steel tubes. Claddings and liners are applied to prevent tubes from corrosive, erosive or abrasive attack.

Bimetallic tube technology

The technology developed by Etubes enables us to produce bimetallic tubes fully metallurgical bonded that are a better substitute for welded overlay, laser cladded and metallurgical cladded plate to tube. Besides that, new area of application can be explored due to the high proven quality and uncommon material combinations.

Unique selling points

- 80% of metal combinations are possible

- The best pure bonding

- In and outside tube cladding

- No limits on dimensions

- Competitive prices due to cost effect production method

Several scientific research reports, performed by research institutes and potential customers, substantiates the statements about quality and possibilities. Each customer requires different material combinations and/or dimensions. Etubes did research for application in the waste-to-energy, oil & gas and chemical & nuclear.

Products

Etubes manufactures bimetallic tubes to the following specifications

Etubes-BiMetallic Cladded Tube

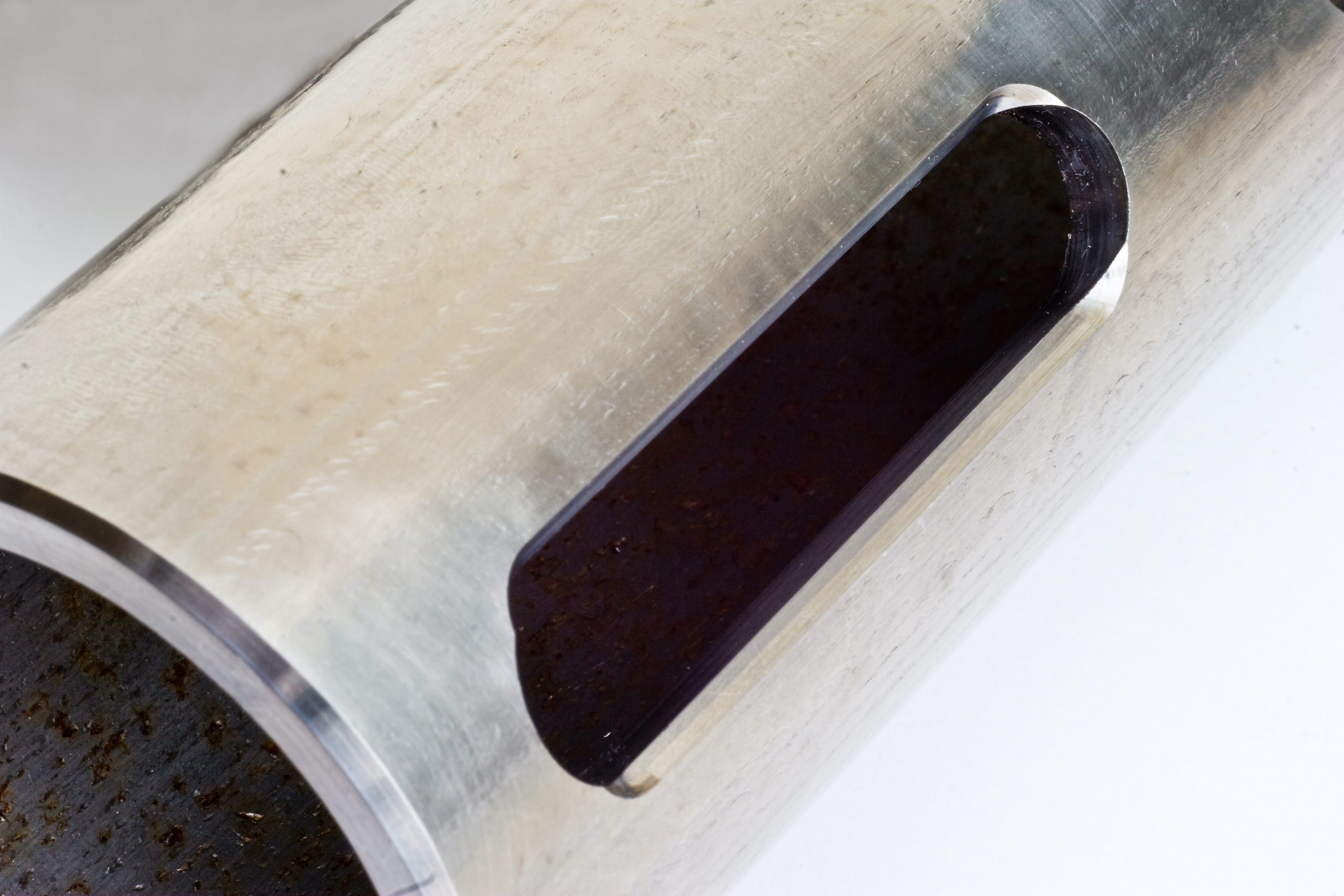

The Etubes-BiMetallic cladded tube is a carbon/stainless steel-based tube with a high-alloy cladding. The production process establishes a full metallic, two-phase bonding between the materials by using an Explosive Welding process.

The tubes are typically applied in coal fired boilers and waste-to-energy plants to withstand the corrosive and erosive impact of the flue gases. The metallic bonding ensures the optimal cooling of the cladding and allows for the manufacturing preparation of return-bends up to 1.2D. Welding procedures are available for circumferential welded joints. Typical cladding materials are Inconel 625, Inconel 686 and various Hastelloy grades applied on A106, 16Mo5 or higher grade base-tubes. Cladding materials can be applied from 1mm to 10mm thickness depending on the base-tube dimensions.

Etubes-BiMetallic Lined Tube

The Etubes-BiMetallic lined tube is a carbon steel-based tube with a high-alloy liner. The production process establishes a full metallic, two-phase bonding between the materials by using an Explosive Welding process. The tubes are typically applied in heat-exchanging equipment such as Syngas coolers and Claus sulphur recovery boilers, for the manufacturing of returnbends in crude heaters and for ethylene furnaces.

Engineering Solutions

High alloy materials have been developed that perform successfully in different processes and against different kinds of attack. The cost of such alloys necessitates a high degree of efficiency in their application.

Traditional cladding techniques utilize arc-welding for applying the cladding layers. This process causes dilution of the cladding with the base-tube and therefore has an impact on the properties of the cladding material. For internal liners, the dimensions of the welding equipment put considerable constraints to the base-tube dimensions.

The Etubes-BiMetallic tubes provide a significant engineering solution. The two distinct factors that determine the selection of material for an application are: the medium it will be exposed to and the mechanical requirements of the function. For both duties the optimum material can be selected without compromising on durability. The two-phase bonding of the materials enables the engineer to make the most efficient use of materials without the need to allow for the degradation of material properties as a result of dilution.

Range of Application

Oil / Gas

separators, absorbers, slug catchers, flowlines, pipelines, catenary risers (SCR), fittings

Chemical Industry

columns, pressure vessels, reactors, heat exchangers

Fertilizer Industry (Urea, Ammonia)

strippers, reactors, heat exchangers

Refineries / Petrochemical Industry

columns, reactors, fractionators, vacuum, towers, distillation towers, hydrocrackers, hydrosulfurisers, coke drums

Power Generation

condenser tube sheets, geothermal plants, coal gasification, hydroelectricity (dam gates, shield plates) nuclear plant components, biofuels

Marine / Defense

protective layer for barrels, triclad for shipbuilding

Environmental Technology

flue gas desulphurization (flue gas channels, chimney, scrubbers, ducts) garbage incineration plants

Seawater Desalination

pipes, heat exchangers evaporator shells, water boxes, pump vessels, flash chambers

Pulp & Paper

pulp boilers, bleaching plants, steaming vessels, digesters, evaporators, evaporator pipe plates

Food Industry

boiling pans for breweries, equipment for industrial kitchens, fermenters, premium induction cookware

Shipbuilding

chemical tankers, ice breakers, propeller systems

Others

e.g. transition joints, hydrometallurgy (reactors) metallurgy (electro galvanizing rolls, nitriding salt baths), electrical equipment